Are we ready to manage plastic waste? The question is, indeed, a simple one but addressing the issue is an urgent matter, given that there have been pros and cons of the presence of plastic.

Opponents of the presence of plastic argue that the material can cause damages to the environment. The presence of plastic, especially plastic waste, pollutes the environment and has hazardous effect because they cannot be easily decomposed.

Supporters of the presence of plastic view that a range of aspects of life relies on plastic materials, starting from cloth, cellular phones, cars to kids toys that use plastic as material.

Currently it is hard not to find a modern item that does not use plastic material. According to Edi Rival, General Manager of Technical Service and Product Development of PT Chandra Asri Petrochemical Tbk (Chandra Asri), plastic is one of the most efficient material that has been found. “The major function is to replace the natural material so as not to pose damage to the environment. Plastic resist the overuse of natural material.

Regarding the utilization of plastic waste, Edi reminded that this should be viewed as a social and modern human behavior problem, more specifically they fail to synchronize the technology change with lifestyle. Many people in the society still like those living in the previous era, before 1950’s. They still think that the material that they use to wrap stem from banana or tea oak leaves, leading them to have a habit of disposing the materials carelessly, including plastic.

When examined further, plastic derives from natural oil processing, in the form of organic material. This means that the material should not damage the environment as long as the way of managing it is well adjusted to the change of times by involving technology. “Plastic is made of organic material, namely hydrocarbon. It is too costly to learn that the plastic ends up becoming waste. The material can be reprocessed into a range of products and can even be returned to the origin, namely as oil.

Why is plastic costly material?

Plastic has high economic potential. For example, a used plastic bag is priced at Rp 1,500 per kilogram. After being washed cleanly, the material will cost between Rp 7,000 and Rp 9,000 per kilogram. The material will increase its value if processed into other products, such as asphalt mix, and fuel.

“The material (the untreated plastic waste) will not be alone (and pollute the sea). There must be persons that dispose of it carelessly. We have to change the social behavior and the culture of sorting it out by themselves,” he said.

Referring to data on the Indonesian Olefin, Aromatic and Plastic Industry Association (INAPLAS), the plastic consumption reached 5.6 million tons per year. The consumption of the recycled plastics reached 1 million tons, the remaining 4.6 million tons of plastic that uses naphtha as its feedstock. Of the naphtha-made plastics, 3 million tons remain in the form of packages stored in the shelves and warehouses.

As many as 5 million tons of used naphtha-made plastic are sent to the final disposal site, the remaining 90,000 tons are left untreated at a disposal channel before ending up in the ocean.

Of the total waste in Jakarta, for example, of the approximately produced 8,000 tons of waste per day, only between 14 percent and 16 percent is plastic material. By percentage, the amount is relatively small, Edi said. Tackling the problem of untreated plastic waste that ends up in the ocean entails the involvement of all parties, including the public, the government and private sector.

Taking advantage of technology

Many technologies can be utilized to convert plastic waste into economically high products. But this calls for collaboration from all relevant parties.

Chandra Asri has collaborated with recycling business players and the public to take advantage of plastic bag waste to be processed into asphalt mix.

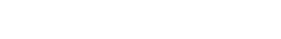

In the first phase, to asphalt an area of 6.372 square meters in Chandra Asri factory needed 2 millions of pieces of plastic waste.

To asphalt a national road that reaches 268,000 km, plastic waste that can be processed into asphalt mix materials reached 536,000 tons or about 10 percent of the national plastic consumption.

More achievements regarding the utilization of plastic waste will be made by the business sector and occupants of housing complexes through the use of the plastic waste as asphalt mix. India, Australia, the United States and many other countries have used the technology that can process plastic waste into the asphalt mix.

Erwanto Wahyu Hidayat, head of the Standard Guideline at the Directorate of Preservation at the Public World Public Housing, said that the technology that coverts the plastic waste into the asphalt mix will have beneficial effect on the environment.

Apart from that, by adding maximum 4 percent – 6 percent plastic waste to the degree of asphalt on the hot asphalt mix, it can increase asphalt mix’ stability up to 40 percent which ultimately increases its durability and make it less prone to cracking.

The calculated plastic waste can be applied to one-kilometer-long road, with 7 m in width and 5 cm in thickness which can absorb between 3 tons and 3.5 tons of the plastic waste.

Teddy Caster Stanturt, head of the Research and Development Center of Green Industry at the Industry Ministry, said that apart from being used as asphalt feedstock, there are many other ways to reduce the plastic waste, one of which is as the feedstock of waste-generated electricity power plant.

What is highly needed in this regard is our commitment to manage plastic waste so that the presence of plastic is more useful, instead of ending up becoming waste.

Waste Management Solutions

Chandra Asri and the Ministry of Public Works and Public Housing (PUPR) recently inaugurated plastic asphalt road located in the company’s plant in Cilegon, Banten to demonstrate the company’s commitment to support the government’s goal to reduce 70 percent of plastic waste by 2025.

The plastic asphalt road is part of the company’s sustainability programs, a method considered as one of Indonesia’s waste management solutions.

Chandra Asri, a subsidiary of PT Barito Pacific Tbk as the majority shareholders, is Indonesia’s largest integrated petrochemical company producing olefins and polyolefins.

The plastic asphalt, stretching on the aforementioned 6.372 m2 area, is made of regular asphalt mixed with 5-6 percent plastic waste weighing around 3 tons.

According to a research conducted by the Ministry of PUPR, the plastic waste mixture can increase resistance level of asphalt deformation.

“We are fully committed to sustainability and eager to contribute to the effort of reducing plastic waste in Indonesia. Mixing plastic waste with asphalt can be one of the solutions to plastic waste problems in Indonesia,” said Erwin Ciputra, Chandra Asri President Director.

“We will also support the Ministry of Public Works and Public Housing and other relevant Ministries to further study the effectiveness and usefulness of the plastic asphalt,” Erwin added.

Chandra Asri receives technical support from the Ministry of PUPR during the development of plastic asphalt road. The Ministry has previously implemented this program in other cities such as Bekasi, Bali, Makassar, Solo, Surabaya, and Tangerang.

Chandra Asri is using plastic bag waste, from High Density Poly-ethylene (HDPE), in the asphalt mix.

Chandra Asri also works hand-in-hand with INAPLAS and Indonesian Plastic Recycle Association (ADUPI) to provide scrap plastic for the asphalt mix.