Influx of imported products hurts local textile industry

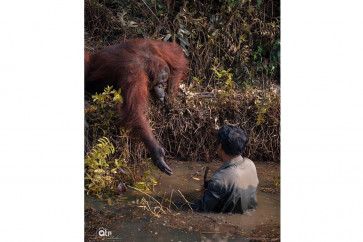

Competing with imports: Workers finish up their textile products in a workshop in Jakarta

Change Size

C

ompeting with imports: Workers finish up their textile products in a workshop in Jakarta. The textile and textile products industry is being squeezed by an influx of cheap imported products from China, weak demand and low regulatory protection for local players. (JP/R. Berto Wedhatama)

The influx of imported textile products has not only caused a widening of the trade deficit but also the closure of local textile factories.

According to the Indonesian Textile Association (API), as many as nine textile factories have been closed and at least 2,000 workers have been dismissed because garment producers prefer to buy imported fabrics.

API’s chairman Ade Sudrajat Usman said that the influx of the imported textile products mostly affected the medium processing industry involved in spinning mills, weaving and knitted fabric production as they have to pay a 5 percent import duty on their raw materials such as thread and filament, while imported fabrics can enter Indonesia without any import duty. As the result, imported fabrics are far cheaper than domestically produced ones.

"This is a red alert for the textile industry," he said at a press conference in in Jakarta on Monday.

Indonesian Association of Synthetic Fiber Producers (APSyFI) secretary-general Redma Gita Wirawasta said that fabric imports increased threefold from 300,000 tons in 2008 to 900,000 tons in 2018, while garment exports stagnated at about 550 million tons over the same period.

The local textile producers said that they were unable to compete because the foreign textile producers carried out dumping practices in the Indonesian market.

In order to protect the local textile industry, API and APSyFI plan to apply to the Indonesian Trade Safeguard Committee (KPPI) for a safeguard policy because the imports have severely injured the local industries.

Ade said the safeguard in the form of an extra import duty would be temporarily established for 200 days while an investigation is underway. Once approved, the safeguard policy would be implemented for three years.

"We believe that the surge of imports has caused injury, so we are going to submit our findings about the dumping practices," Redma said. He said he hoped the government would impose safeguard import duties from the upstream to the downstream industries, such as 2.5 percent on fiber, 5 percent to 6 percent on yarn, 7 percent on fabric and between 15 and 18 percent on garments.

Redma said that the safeguard import duties were needed to protect the local upstream and downstream textile industries from cheap imported products.

In addition, the local textile industries also want the government to stop issuing permits to import textile-related products except those for export-oriented industries located in industrial bonded zones. Another demand is for the revision of the Trade Ministerial Regulation No. 64/2017, which allows general importers to import fabrics, yarns and fibers.

The Indonesian textile products are not as competitive as those from other countries because of the long lead time, the total amount of time required for completing a product beginning from the date of receiving the order to the shipment of the goods to customers.

The CEO of Busana Apparel Group, Marimutu Maniwanen, said that the lead time of the Indonesian textile industry can be 120 days, while in other countries such as Vietnam and Bangladesh it is only about 60 days.

The lead time is too long because the majority of raw materials for the textile industry in Indonesia are still imported. "If we import raw materials, it is difficult to reduce the lead time. At most, it can be reduced to 90 days. To reach 60 days, we must procure all raw materials from within the country," he said.

He said that labor regulations, the price of energy and high interest rates also contributed to the undesirable investing climate in the country.

Redma said in July that last year that the factory used of fabrics was at 61.5 percent of installed capacity, fiber at 67.7 percent, yarn at 76.5 percent and garments at 86.9 percent. The factory use is low because of the lack of orders. (eyc)