Popular Reads

Top Results

Can't find what you're looking for?

View all search resultsPopular Reads

Top Results

Can't find what you're looking for?

View all search resultsAnalysis: Knitting up RI's textile, garment industry amid global slowdown

The government is pinning high expectations on Indonesia’s textile and garmet industry in 2020 following positive growth booked in 2019

Change text size

Gift Premium Articles

to Anyone

T

he government is pinning high expectations on Indonesia’s textile and garmet industry in 2020 following positive growth booked in 2019. However, a week after the signing of the phase one trade deal between the United States and China, skepticism continues to increase and affect this industry.

Such an external challenge serves as one of the main issues for the textile and garment industry. Internal improvements such as those achieved by addressing the industry’s competitiveness and efficiency are expected to enhance trade and investment, thereby helping tackle external threats.

Indonesia’s domestic garment and textile industry recorded remarkable growth in the third quarter of 2019, having enjoyed 15.08 percent year-on-year (yoy) rate. That is higher than the national economic growth of 5.02 percent during the same period and compared with the 10.08 percent growth booked by the textile industry in the third quarter of 2018 yoy. The textile industry’s growth was driven by the rise of domestic demand.

In terms of exports, shipment of Indonesian garment products to the world from January to October 2019 decreased by 3.6 percent yoy to US$7.15 billion. That compares with $7.42 billion from January to October 2018. According to estimates by Bank Mandiri’s Office of Chief Economist research team, total garment exports by the end of 2019 will be worth $9.9 billion.

The garment industry contributes more to exports than the textile industry. In 2018, the top three destinations for Indonesian garment exports were the US, Japan and Germany with total export values reaching $4.5 billion, $950 million, $470 million, respectively. For textile exports, the top three destinations for Indonesia in 2018 were China, Japan and Turkey, with export values respectively at $520 million, $480 million and $470 million.

From January to October 2019, the worth of Indonesian garment exports to the US dropped to $3.99 billion from $4.05 billion in the same period of 2018, although US garment imports from around the world increased by 2.59 percent to $90.8 billion in January to October 2019 from $88.5 billion in the same period a year earlier.

In the 10-month period that ended October 2019, the market share of Indonesian garments in the US fell to 4.4 percent from 4.6 percent in the same period of 2018. By October, the US’ top five garment importers were China, Vietnam, India, Bangladesh and Indonesia with market share respectively at 35 percent, 13.3 percent, 6.7 percent, 5.8 percent and 4.4 percent.

The decline in Indonesian garment shipments to the US was due to trade diversion to Vietnam, as reflected by the Southeast Asian country’s increasing market share to 13.3 percent in October 2019 from 12.4 percent in the same period a year earlier.

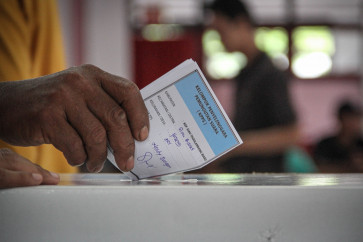

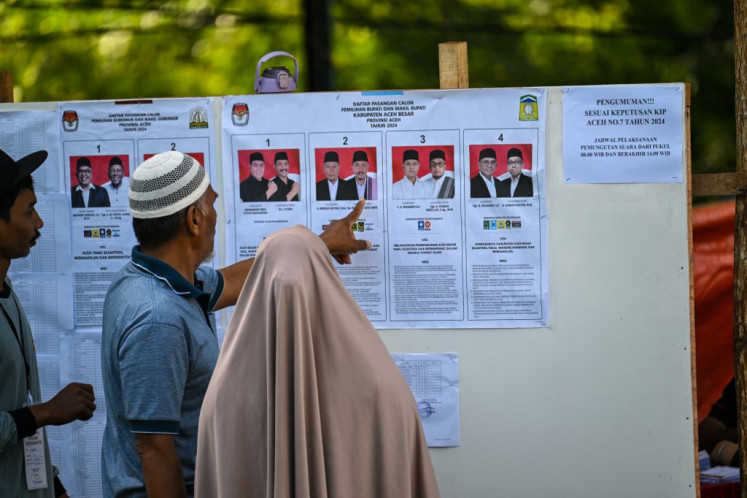

Although exports of Indonesian garment products to the world showed negative growth, domestic demand continues to grow, especially during simultaneous elections and the Idul Fitri holiday season.

As for textile imports, their value decreased to $6.2 million in January to September 2019 from $6.6 million in the same period of 2018. The declining imports in the textile and garment industry were backed by domestic players’ investments in rayon fiber production, which positively affected production costs in the upstream industry, making them more efficient.

More positive developments in 2019 were the signing of the Indonesia-Australia Comprehensive Economic Partnership Agreement and the European Free Trade Association. The deals could expand export markets for Indonesian manufactured products as they would waive import duties on a number of Indonesian products, including garments and textiles.

The government is also engaging in trade negotiations with the US and the European Union to make Indonesian textile products more competitive.

Indonesia’s garment and textile industry is still hindered by external and domestic problems. On the internal side, the same old problems have not been fully solved by the government. Gas and electricity prices in Indonesia, for instance, are still among the highest among textile producing countries. This has scaled down the industry's competitiveness.

Furthermore, labor cost issues have exacerbated the business environment for the industry. Indonesian wages, especially in West Java and Jakarta, have considerably increased in the last several years. This has prompted global and regional investors to increase automation in order to reduce the number of workers or relocate their factories to cheaper provinces and, in some cases, other countries.

Moreover, aging machinery and equipment has diminished production efficiency, particularly for traditional and small-scale players in the sector. Currently, 30 percent of textile factories in Indonesia use machinery that is more than 25 years old.

Since 2007, the government has provided incentives for revitalizing machinery. However, the allocated funds are inadequate for replacing machinery in the entire industry. Furthermore, a recent incentive by government was an income tax cut of 30 percent for six years through the issuance of the Industry Ministerial Regulation No. 1/2018.

On the external front, the impact of a trade war has shocked the domestic textile market with a flood of Chinese products that has put a big constraint on Indonesian textile manufacturers. The rupiah exchange rate has significantly determined the industry’s production costs. This is due to a significant portion of the Indonesian textile sector’s raw materials, such as cotton, being imported and priced in US dollars. According to the Indonesian Textile Association, raw material prices have increased by 5 to 6 percent in 2019.

Small and medium textile companies are the ones affected the most as they import raw materials and pay in US dollars but sell in rupiah. On the other hand, bigger companies export their products and they earn the stronger US dollar as it enhances their revenues. If the current currency situation persists, many small and medium textile companies will close down their factories.

Indonesia’s competitiveness in the global textile and garment industry has been beaten by its competitors, particularly Vietnam, Bangladesh and Cambodia. In the last few years, these three countries have achieved higher export growth than Indonesia. Vietnam gains the most from Europe and the US, as Vietnam has a trade agreement and close relations with the US. The EU and the US enjoy zero percent import duty on textile products, while Indonesia is liable to 5 to 20 percent import duties.

The ongoing regional competition pressure in the textile and garment industry would continue to persist because of the prolonged trade war between China and the US, driven by US President Donald Trump’s protectionist policies. This has taken its toll on emerging economies, including Indonesia’s.

Despite all the challenges, the government remains optimistic that the textile and garment sector will continue to show high growth in 2020. The Industry Ministry expects textile exports to scale up to $15 billion and help create new jobs. Production capacity is estimated to increase to 1.64 million tons annually with an investment value of Rp 81.45 trillion.

In order to achieve this, the Indonesian government should enhance its support for the industry. This includes improving law enforcement in the handling of potential illegal textile imports, accelerating industrial area development outside of Java to reduce logistics costs and establishing vocational schools to prepare skilled human resources who are able to tap into the latest technology.

_________

The writer is an industry analyst at Bank Mandiri.