Popular Reads

Top Results

Can't find what you're looking for?

View all search resultsPopular Reads

Top Results

Can't find what you're looking for?

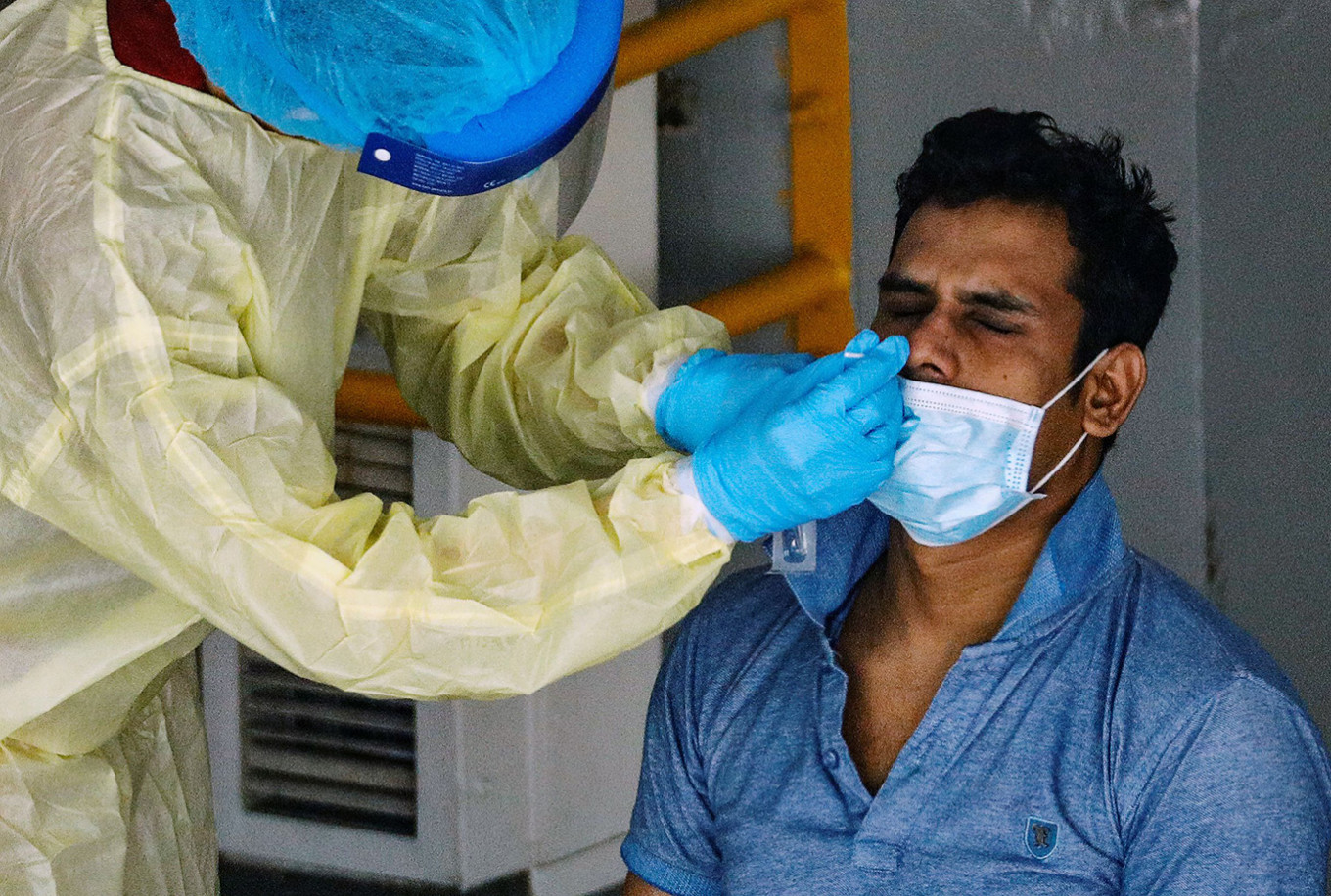

View all search resultsSingapore’s nasal swab struggle shows why test kits are scarce

“If a country is not a producer, it then just has to make do with what is allocated and learn to prioritize,” said Jeremy Lim, an adjunct associate professor at the National University of Singapore’s Saw Swee Hock School of Public Health. “It’s exquisitely painful to be helpless.”

Change text size

Gift Premium Articles

to Anyone

In a back room of Singaporean dentist Teehee Dental Works, three orange-topped boxes hum with a sterile buzz.

Over the next three hours, a thousand strands of liquid resin will form and harden to become plastic nasal swabs, ready to be used in Covid-19 test kits. Those 3D printers – normally making dentures and crowns – are a part of a local effort to re-tool some of Singapore’s industries to respond to a growing need for test kits amid the widening coronavirus pandemic.

With one of Asia’s largest outbreaks following a resurgence in infections, the city state is trying to change strategy, pivoting from selectively screening for cases to the mass testing deployed successfully in places like South Korea. But Singapore’s bid to expand testing fivefold from 8,000 a day to 40,000 by later this year comes amid surging global demand for kits and their components -- from nasal swabs to chemical reagents -- as outbreaks in the US and parts of Europe persist.

And as the clamor for kits is only set to intensify as testing provides a route to re-opening locked down economies, Singapore may have to lean on local industry to help fill the shortfall. Without the manufacturing capacity of China and lower-cost countries in Southeast Asia, domestic firms -- from dentists to aircraft part-makers, engineering companies to metal forgers -- are trying to plug the nation’s need for kits.

“If a country is not a producer, it then just has to make do with what is allocated and learn to prioritize,” said Jeremy Lim, an adjunct associate professor at the National University of Singapore’s Saw Swee Hock School of Public Health. “It’s exquisitely painful to be helpless.”

Singapore’s challenge has been compounded by its late shift in strategy to mass testing compared to countries like South Korea. Although the first signs of what would become a massive outbreak among the country’s army of low-paid foreign workers emerged in early February, Singapore seemed to continue to apply tactics used to contain the Severe Acute Respiratory Syndrome, or SARS, outbreak 17 years ago. The new coronavirus has proved much more contagious, with countries that tested widely seeing more success in quashing their epidemics.

Singapore didn’t signal a shift to concerted mass testing -- where testing is conducted widely in a vulnerable community beyond just those who had confirmed contact with an infected person -- until April. In the interim, the coronavirus went global and countries began snatching up supplies of testing materials and hoarding their own production.

‘Feel the Challenge’

In February “we could get things in within three days to a week and we could get things out pretty easily,” said Zhou Lihan, chief executive officer of MiRXES, which produces test kits for governments and hospitals in 25 countries around the world. “Once we hit late March - that was where we started to feel the challenge.”

Singapore-based MiRXES is currently churning out the Fortitude 2.0 testing kit designed by Singapore’s Agency for Science, Technology and Research, known as A*STAR, and Tan Tock Seng Hospital. Where his firm was able to produce 100,000 kits a week in early February, it can now make 500,000 over the same period.

Even that may not be enough. “In the initial days, at any point, we had enough plastics and other basic materials to make half a million to a million tests. Previously we did that to plan for a 3-6 month manufacturing cycle,” said Zhou. “With exponential testing globally, suddenly that kind of stock can only last you a month or even a week at some points.”

The coronavirus manifests in some people without any outward signs of sickness, raising the risk they could be silent spreaders. That means widespread and repeated testing of people before they return to workplaces is likely the main way governments will be able to protect against future waves of infection.

Acumen Research Laboratories -- a Singapore biotech firm that was mainly a designer rather than producer of test kits before the crisis -- has shifted its supply chain over the past few months to manufacture Covid-19 test kits and analyze their results. The company is now capable of processing 20,000 tests daily, equivalent to a fifth of the U.K.’s total daily target.

“A test kit is composed of many, many sub-components -- more than 20 -- so if any one of those is short you don’t have a kit,” said director Ong Siew Hua. “The lesson learned from all of this is that in ‘peacetime,’ you must invest in things that sometimes you take for granted.”

No Timeline

Singapore’s Health Minister Gan Kim Yong told parliament on Monday that the government cannot set a timeline to boost testing to 40,000 a day: “I won’t be able to promise you when, but we are doing our best to ramp it up.”

The country’s health as well as trade and industry ministries did not answer questions on how many test kits Singapore is currently able to manufacture locally or is procuring on the global market.

While Singapore was initially lauded for its comparatively even-handed approach to containing the virus -- opting for social distancing and awareness over a lockdown -- it emerged in April that the pathogen had been spreading among migrant workers who live in cramped dormitories throughout the city. An explosion in those cases saw its total tally balloon from a few hundred in early March to more than 20,000 now, making it Asia’s most infected nation after China and India despite its small population.

Now in the fifth week of a population-wide lockdown imposed as the second wave of cases emerged, experts say the ability to test widely will be key to getting Singapore back to a position where it can consider easing restrictions. In China, where the virus first emerged, most business and industrial activity has resumed, with companies requiring workers to test negative before returning to offices or factories.

Test kits -- which identify if the coronavirus’ genetic sequence is present in a person’s sample -- comprise dozens of components, from nasal swabs to chemicals with names like taq polymerase that help amplify the viral DNA so it can be detected.

Because of its lack of low-end manufacturing capacity, some of Singapore’s worst shortages have actually been in basic, cheap components like swabs that are inserted into a person’s nasal cavity to retrieve the sample to be tested. In a Facebook post last month, Ho Ching, chief executive officer of state investor Temasek Holdings Pte and the prime minister’s wife, gave the example of a “gold standard swab producer” in Italy that had supplied all of Singapore’s hospitals “turning inwards” as the European nation shifted resources to its domestic outbreak.

15-cm long stick

But as new local producers like Teehee Dental are finding, the humble nasal swab is more difficult to make from scratch than it seems.

Teehee Dental Works, a clinic in Singapore’s glitzy Orchard Road shopping district, first put its 3D printers to work after one of founder Yang Xiao’s relatives caught the virus last month. Between patients, Yang and his team scoured the internet searching for instructions on how to make the perfect nasopharyngeal swab.

“It sounds fairly simple to make a stick,” he said. “But once you get into the process of it you quickly realize it’s a difficult process to get to the final design.”

After 15 tries, they finally landed on a model with the right balance of thickness and thinness to be used effectively and reproduced in large batches: 15cm long with a latticed head made of biomedical plastic. Several packs have already been sent to hospitals and clinics in Singapore and its neighbors as well as parts of Europe for clinical trials.

Other local companies like 3D printing firm Chemtron, which usually manufactures drones and jewelry, are ready to start making swabs as well, said business development manager Tony Moochala.

Moochala said his team brought home their eight 3D printers since their office closed. “They’re on standby 24 hours a day, seven days a week.”