Popular Reads

Top Results

Can't find what you're looking for?

View all search resultsPopular Reads

Top Results

Can't find what you're looking for?

View all search resultsTons of trash, less to recycle: The irony of recycling plastic waste

Recycling technology could be the solution to the plastic waste problem in Indonesia. How serious are we in dealing with this issue?

Change text size

Gift Premium Articles

to Anyone

Recycling technology could be the solution to the plastic waste problem in Indonesia. How serious are we in dealing with this issue?

Plastic waste, which disproportionately pollutes the soil, air and water, is often considered the biggest enemy of the environment. Based on data from the Environment and Forestry Ministry, of 68.5 million tons of waste Indonesia in 2021, as much as 11.6 million tons, 17 percent, is plastic waste. Of that number, according to data from the Indonesian Movement for the Plastic Bag Diet in 2019, only a maximum of 9 percent can still be recycled.

In most big cities, waste originating from households, industry and from other places is dumped into landfills and piles up continuously like hills.

When recycled, though, plastic waste has an economic value. Ironically, the percentage of plastic waste processing in Indonesia is not yet maximized. In the city of Medan, North Sumatra, for example, the volume of waste amounts to around 2,000 tons per day, and only 30 percent of the total waste can be recycled, including plastic waste.

One of the reasons for this problem is because plastic recycling is still difficult to sustain due to a shortage of raw materials, namely plastic waste itself.

"This is ironic. On the one hand, there is a lot of plastic waste around us, but why is there a shortage of plastic raw materials for recycling? [This] shouldn't [happen], because plastic waste is all around us," Bobby Umroh, an engineer that creates machines for plastic waste recycling at Star Mesin, his workshop in Medan, told The Jakarta Post in early May.

He added that a number of people who ordered waste-recycling machines — plastic-cleaning machines and plastic choppers — on average faced the same problem: They found shortages of raw materials for plastic waste that could be processed.

The answer to this problem has actually been found. According to Bobby, the low percentage of waste recycling can be overcome with appropriate technology. But this solution is not that easy to implement because garbage collection is still done manually. Waste recyclers source plastic waste from scavengers. The supply is limited because not many people want to be scavengers as the price of plastic waste is still low.

Generally, scavengers sell plastic waste made from polyethylene (PE), such as plastic shopping bags for 5 US cents per kilogram and plastic waste made from polypropylene (PP), such as used drink bottles for 34 US cents per kg. Then, the recycler cleans and chops it and sells the recycled PE plastic for 34 US cents per kg and PP plastic for 89 US cents per kg to the plastic processing factory.

"This means that the plastic that is scattered around us is a source of money. It's just that there is no system that can be applied to deal with it. So far we have only relied on scavengers," he said.

“If there are no scavengers, the waste that accumulates in the final waste disposal site [TPA] will continue to grow each year. Imagine that,” he added.

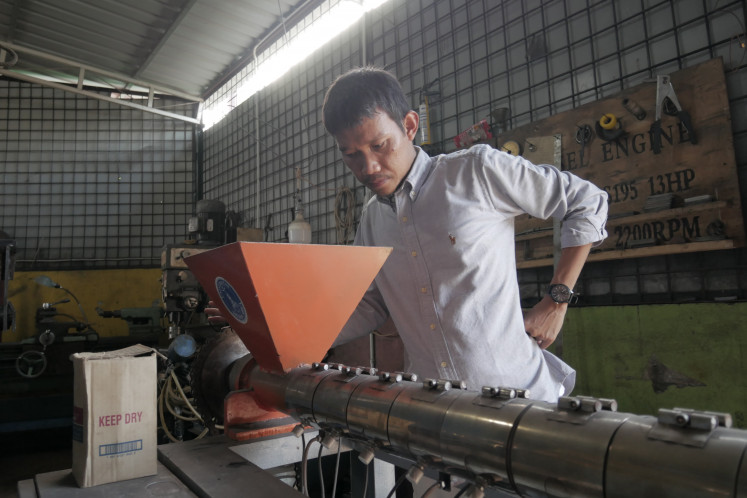

Forward-thinking: Bobby Umroh, a mechanical engineer, is trying to find a solution to the problem of recycling plastic waste, such as the lack of plastic recycling raw materials. (JP/Tonggo Simangunsong) (JP/Tonggo Simangunsong)Economic value

A plastic recycler in Pematangsiantar, North Sumatra, Feri Hixon Siahaan, told the Post that he has not been able to rely on scavengers. But he employs two people at the TPA, who are able to collect a minimum of 20 kg of plastic per day.

"[However], not many [people] want to be scavengers, because it may take a long time to collect plastic waste and the selling value of the waste is still much lower than the plastic that has been recycled," he said.

Apart from the two people he employs, Siahaan also buys plastic waste from waste collection for Rp 3,000 (20 US cents) per kg. Of the 80 tons of waste he recycles using machines, he can earn up to an 80 percent margin after selling it to a plastic processing factory.

"Yes, it's true. Most people often think that plastic is waste, but actually most of the plastic can be recycled and has a high economic value," he said, adding that the lack of recycling technology used to be a major problem. Now, that problem has started to be overcome with the availability of locally made recycling machines.

"These machines are very helpful in recycling. The machine we use can operate for five hours and clean and chop 500 kg of plastic waste. In the future I plan to increase its capacity," he said.

Getting the job done: Bobby Umroh is working at his recycling workshop, Star Mesin, in Medan. (JP/Tonggo Simangunsong) (JP/Tonggo Simangunsong)Government support

In addition to having created a recycling machine that has been used in several regions in Indonesia, Bobby is currently designing waste-sorting technology at the landfill that tries to minimize the number of scavengers involved. After being delivered to the TPA, the waste is immediately sorted using a sorting machine, including selecting the waste from raw materials for compost. This machine still involves humans to place the waste according to its category, including plastic waste.

This technology at least also overcomes the problem of a lack of raw materials due to an inadequate number of scavengers.

Meanwhile, Bobby has also designed technology that still involves human resources to sort out the types of waste that have been separated by machines.

“The reason for the lack of scavengers may be because there is a sense of shame, because they consider this job to lower their self-esteem. Those who don't have jobs or have been going around collecting trash no longer need to do the same thing. They will only work in one area, so the issue of shame is also resolved," said Bobby.

However, this appropriate technology requires serious attention from the government. For example, the government can support it by running a plastic-recycling program at least once in each sub-district to raise awareness. The program should also involve environmental activists and engineers, so that the activity runs according to procedural standards. The involvement of engineers is important to maintain and upgrade technical needs, while environmental activists can help organize the community in the waste-sorting process.

"I hope there is one program in a sub-district that can be used as a successful starter, so that other regions will follow suit," he said.

Bobby adds that advancing technology is a better solution than expanding landfill areas, which will only take more land and cause more air pollution.

An example of this is the TPA Terjun in Medan. “From time to time, the TPA seems to be unable to absorb the waste of Medan residents,” said Bobby. “This problem could be overcome without expanding the waste disposal area because, if we want to, the waste can be recycled, including plastic.”

"Again, this requires the government's serious support. The technology already exists, it's just a matter of whether [and how] we want to apply it," he said.